Talk with us today about your project. We make it easy to browse, design, select and plan for your new wide plank floors with your own personal Carlisle Wide Plank Floor Specialist.

Solid vs. Engineered Wood Floors

When it comes to selecting wood flooring for your home, you have many decisions to make. What species? Do you want a smooth or distressed floor? What color do you want? But one of the most important questions is what type of floor “construction” do you want… solid wood or engineered wood?

The Difference

Solid wood flooring, as the name implies, means that each flooring board is made from one solid piece of wood. It is often assumed that solid wood flooring is not as stable as engineered wood flooring, but depending on the manufacturer, that is not always the case. We recommend researching the quality standards that are being applied to your solid wood floor before making a final decision about its stability.

For example, Carlisle floors are made from old-growth heartwood to ensure a tight, dense grain pattern for strength. Plus, each board undergoes an extended drying process. And unlike other flooring manufacturers, we apply our traditional Carlisle Custom Coat™ pre-finish to delay moisture absorption. As a result, we’ve been able to install our solid wood flooring over every type of radiant heat system and concrete surface for over forty years.

Engineered wood flooring means that each flooring board is made up of multiple component layers, to achieve the desired thickness and wear. Engineered flooring is often perceived as more stable than solid wood, but it can depend on the manufacturer, construction, quality characteristics (which we will talk about later) and where the flooring is going to be installed. When installing flooring in drier climates, engineered flooring may actually be less stable.

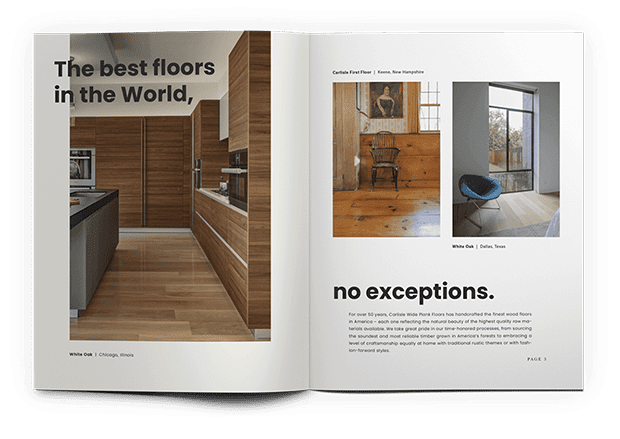

Endless Inspiration for the Floor of Your Dreams

GET DESIGN BOOKFloor Dimensions

Most people researching solid wood flooring and engineered wood flooring might not realize that the dimensions between the two options can be quite different. You may not be able to get the same widths and lengths with engineered wood as you can with solid wood. This depends on the manufacturer you are working with.

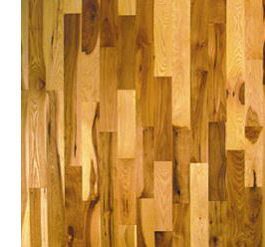

For example, about 90% of the floors available today as an engineered product are only available in sizes up to 6′ long with an average board length of about 2′. Likewise, each board tends to be no wider than 4-5″. Using short, narrow flooring boards, such as in this Hickory flooring example (above right), will result in a floor with many more seams and joints. This will make your room, and your overall space look very busy.

Some manufacturers offer engineered wood flooring in the same widths and lengths as solid wood flooring options. This will dramatically improve the overall look of your floor, as in this example of a wide plank Hickory hardwood floor installed in a home in Florida. It features engineered wood flooring crafted in 8″ wide boards, up to 12′ long and installed directly to a concrete slab. Engineered hickory floors are among the strongest and most durable options for your home.

Floor Thickness

Solid wood flooring comes in a variety of thicknesses: typically 1/2″, 5/8″ and 3/4″. There is very little difference in cost between 1/2″ thick and 3/4″ thick because you start with the same raw material when you make the flooring. So making a floor 1/2″ thick actually produces more waste than making a floor that is 3/4″ thick.

Engineered flooring also comes in a variety of thicknesses. There are two components of “thickness” when considering engineered flooring — that of the “backing,” which provides the structure for the flooring, and the “wear layer” which is the surface you walk on after it is installed (we’ll talk more about Wear Layer in the next section). The backing of an engineered floor is comprised of multiple thin layers of wood which can include quality plywood, OSB, or other hardwood or softwood configurations.

When looking at engineered flooring options, the backing should be thicker than the wear layer to create the most stable engineered wood flooring plank. If you are considering a floor where the backing and wear layer are of a similar thickness, you can run into problems with stability in areas where there may be excess moisture or seasonal changes in moisture and humidity.

Wear Layer

The wear layer of your floor refers to the material above the tongue and groove — the part that you walk on. When considering solid wood floors or engineered wood flooring, you ideally want a 3/16″ thick wear layer. However, most engineered floors are made with a very thin layer, equivalent to only 3 sheets of paper! This means that the wear layer of your floor will wear very quickly, it cannot be refinished or sanded, and your floor will need to be replaced more frequently. If you choose a wood floor with a thicker wear layer, you will ensure that your floor lasts longer, can be refinished (if necessary), and will present a lower cost of ownership over the life of your floor!

An important note about thickness and wear layer: the thickness of your backing and wear layer have a direct correlation to the cost of the product — the thinner the wear layer is, the less expensive the floor will be. While this might present a very economical solution, these thinner engineered floors don’t last long!

While it might cost more up-front to invest in higher quality solid wood floors or engineered hardwood flooring with a thicker wear layer, you will be buying a floor that lasts longer and will cost less to maintain over time.

Your Preferences, Your Jobsite, Your Installation

Some people choose solid hardwood flooring or engineered wood flooring based on aesthetics. They want wider boards, longer lengths or both. But the most critical factor to deciding between solid or engineered is the type of home you live in, where your home is located, and your preferences as to the performance of your floor from season to season. It can also depend on what type of installation you are performing, and who will be completing the installation.

Answering these questions will help you determine which type of flooring construction is right for you:

- Do you mind if your floors expand and contract between the seasons or get small gaps during the drier months, or do you prefer floors with very little expansion and contraction?

- Will you live in your home year-round or is it a seasonal home?

- What type of wood are you interested in — hardwood floors or pine flooring?

- Are you going for something colonial? A historic look? More modern?

- What type of installation are you considering — at- above- or below-grade? Concrete slab? Radiant heat? Plywood substrate?

- Who will be doing the installation — will you do it yourself or hire a professional?

– – – – – –

More questions? Download our Solid vs Engineered Wood brochure to learn more about the differences and similarities between solid and engineered wood flooring, and explore how to choose the best one for your project.