Take the next step in the planning process, let us outline an estimate for your favorite wood flooring.

How to Choose Between Prefinished or Site Finished Wood Floors

One of the most important decisions, regarding your new wood floor, is choosing between getting it prefinished or having the floor finished on-site. Each choice has its pros and cons, from easier stain matching to significant time and cost savings. And while each has its proponents, Carlisle’s unique approach has made prefinished wood flooring the preferred choice. Before you decide, explore the differences and select the one that aligns with your priorities.

History of Site Finishing & Today’s Approach

For years, on-site finishing has been the preferred choice of homeowners and contractors for a variety of reasons. Site applied stains allowed for custom colors to get just the right look — this is especially useful when trying to match existing wood. Site applied finishes also seemed to have a better appearance. But, the other reason was a general concern about the quality of the finish available on most mass-produced prefinished floors, which were nearly impossible to touch up over the years whereas it was easy to recoat a site applied polyurethane.

Traditionally, on-site finishing has also been the only way to get special widths and lengths of flooring as well as other design options, such as non-beveled edge profiles. Plus, since it should be the last step in construction, it affords the opportunity to fix any dings or scratches made to the floorboards during construction, before applying the finish. If it’s not the last step, then construction will need to be shut down for finishing and touchups will probably be needed later.

On the other hand, on-site finishing is very time-intensive. It takes a long time to sand and clean the wood flooring, get the environment set and stable, apply the stain and topcoat (which is typically 3-4 coats), and wait for each application to dry. This can run from a matter of days to several weeks. During this time you need to limit access to the job site, you can’t walk on the floors or put furniture on them. In addition, the vapors from some finishing products can linger for a while which may be uncomfortable to those with environmental sensitivities, small children or pets.

On the other hand, on-site finishing is very time-intensive. It takes a long time to sand and clean the wood flooring, get the environment set and stable, apply the stain and topcoat (which is typically 3-4 coats), and wait for each application to dry. This can run from a matter of days to several weeks. During this time you need to limit access to the job site, you can’t walk on the floors or put furniture on them. In addition, the vapors from some finishing products can linger for a while which may be uncomfortable to those with environmental sensitivities, small children or pets.

When you order unfinished hardwood flooring you are putting a lot of faith into the skill and commitment of the sander and finisher, as well as the stain and finish products they will be using on your floor. You see, when you sand a wood floor it can completely transform the way the stain and finish take to the wood. If you order unfinished wood flooring from Carlisle, you may have less to worry about because we mill our floors to about 1/20,000 of an inch, which means that our floors normally require little, if any, sanding after installation — depending on the quality of the installation and subfloor. This makes the finishing process go so much smoother.

Make sure you do your homework to understand the quality of the milling, and how much sanding may be required after installation, even if you save money upfront on the cost of the wood flooring, you will end of paying the difference, and then some, for installation on-site for a poorly milled wood floor. Wood floors from other suppliers may require multiple sanding steps, which is costly, cumbersome and can present project delays. You also want to make sure you have a clear understanding of the stain and finish your installer/finisher will be using. They should provide multiple samples of each stain you are considering, in order to give you a better idea of how it will look on your floor. Wood is a natural product and you should expect some variation in color based on how the stain or finish absorbs into the nuances of the board. Multiple samples and photography can help ensure you have the best expectations for the appearance of your floor, once installed and finished.

There are some scenarios where a site-finished floor may be more appropriate, even given the potential drawbacks noted above. For example, this is a good solution if you are trying to match an existing floor that is already in place; or if you are working on a historic restoration project using very wider boards such as 13-20″ Eastern White Pine.

Endless Inspiration for the Floor of Your Dreams

GET DESIGN BOOKPrefinished Flooring Should be Convenient & Beautiful

Having continuously evolved since their introduction many years ago, prefinished floors save time and money because they’re ready to walk on as soon as they’re installed without all the prep work required for site-finished floors. (If construction is still going on after flooring installation, steps should be taken to protect the floor.) There’s also no need to suspend construction, hire an installer or hire a finisher – this can sometimes make it easy for you to work with your builder to install the floors, eliminating the need for another subcontractor. Plus, they usually feature an attractive, highly durable finish with an ever-expanding selection of colors.

However, you want to address some common drawbacks of prefinished wood floors with answers to these four questions:

- Will the finish have a “plastic” look that takes away from the overall appeal of the floor?

- Are wider widths and longer lengths available?

- Does the flooring have a micro-bevel which will amplify the visibility of seams?

- How easy will it be to touch up and refinish the prefinished flooring?

- How can you ensure the color is going to be right?

- Am I limited to what colors I can have?

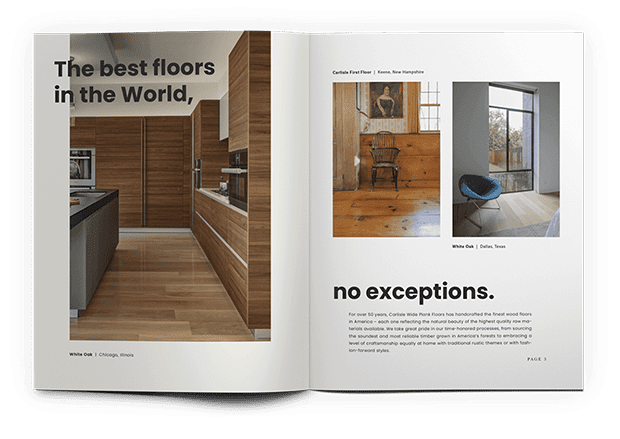

Fortunately, Carlisle Wide Plank Floors utilizes a unique prefinishing process that avoids all of these issues. Combining time-honored techniques with modern technology, Carlisle creates prefinished wide planks with the beauty of a deep hand-rubbed appearance that is also very durable. And, because each floor is made to order, they can develop one-of-a-kind custom stains to give you the exact look you want — that includes gold, grays, blacks, whites and anything in between.

Fortunately, Carlisle Wide Plank Floors utilizes a unique prefinishing process that avoids all of these issues. Combining time-honored techniques with modern technology, Carlisle creates prefinished wide planks with the beauty of a deep hand-rubbed appearance that is also very durable. And, because each floor is made to order, they can develop one-of-a-kind custom stains to give you the exact look you want — that includes gold, grays, blacks, whites and anything in between.

Carlisle prefinished wood floors also average 8″ wide, and 2-12′ long, so you have no compromise in width or length and overall look. Carlisle also goes the extra distance by using a much smaller softened edge profile to help minimize the appearance of seams. In addition, you can easily recoat the finish with a dustless recoat kit — no sanding required and touch-ups can be done in a matter of hours.

Most prefinished wood floors on the market are mass-produced, literally thousands of square feet at a time, you could be 10 boxes at one time and there is no guarantee that it is all going to match because the flooring could have been made weeks or months apart just to fill inventory for a particular SKU. Then there are some flooring manufacturers, like Carlisle, who use client approved control samples to check the color and finish throughout the entire process of making a new floor to ensure it matches up.

A prefinished wood floor can be a great solution for homeowners, or commercial projects, where you have a small window of time when the floors can be installed, or if the client wants to install the flooring themselves. Although some may think prefinished flooring is only suitable for renovations or rehabs, they are also appropriate for entire home remodels and new constructions since they are so much more convenient and quicker to install.

– – – – – –

Choosing between pre-finished or unfinished wood flooring is about choosing the best option for you. Download the complimentary Smart Buyers Guide to Selecting the Right Flooring, to see more color and finish examples and learn more about pre-finished flooring.