2 Ways to Create a Dark Wood Floor

Dark wood flooring is a very popular look for interior designs today. We hesitate to use the word “trend” since that implies this look transitions in and out of style. The truth is that dark wood flooring harkens back to an age of the original pine floors when people would stain their boards with tobacco soaked in turpentine. Considerable advancement has been made since then, to produce wood floor stains that are authentic, beautiful, and more environmentally friendly.

Today, there are two ways to create a dark wood floor, some are easier than others, and the final decision really comes down to the look you want to create…not to mention that “dark” has different meanings to every client.

Today, there are two ways to create a dark wood floor, some are easier than others, and the final decision really comes down to the look you want to create…not to mention that “dark” has different meanings to every client.

Naturally Dark Wood Flooring

Naturally, dark wood floors are very rare. Domestic wood, like American Black Walnut, or imported woods, like Wenge are the most common species.

There is a wide variety of quality when it comes to American Walnut flooring, and although grades exist, they apply more to lumber, furniture, and cabinetry; they have little to do with wood flooring. For this reason, not all Walnut is created equal. The quality of the wood and the grading process used will determine the final look. For example, not all Walnut is steamed, but that process brings out more of the rich color of the wood. Walnut, naturally has some extreme color variation ranging from maple in color to the dark chocolate brown. Without the right grading standards, and people in place to monitor the grading — such as we employ at Carlisle — you cannot guarantee a consistent appearance.

Imported or exotic wood floors, like Wenge, can also be dark naturally, but they have a completely different grading standard than those of domestic woods — whether for flooring or lumber. One should expect an extreme amount of color variation in exotic woods due to the size of the timbers being harvested, and the fact that most exotic wood floors are mass-produced, in such large volumes, there is no way to grade for any kind of consistency. Grading related to exotic wood flooring is really limited to how “clear” or “rustic” the boards are. Some exotic woods are very difficult to stain, as the grain density of the wood makes the stain nearly impenetrable. So make sure you like the wood, the color, and the variation in its natural state.

Endless Inspiration for the Floor of Your Dreams

GET DESIGN BOOK Staining your Wood Flooring

Staining your Wood Flooring

Depending on what “dark” really means to you, will dictate whether this method is an option — staining the floor. There are also a few scenarios where using a stain may be more appropriate:

- Natural walnut not quite dark enough

- Exotic wood floors have too much variation

- You want a more consistent color or look

- You want to “match” woodworking

If you fall into one of the above scenarios, considering a stain should definitely be on your to-do list. This may also be a great way to save money on your overall flooring project since Walnut hardwood flooring tends to be more expensive than other options.

The decision to use a stain on your wood floor opens up a world of possibilities, especially since the most popular wood floors — hickory, ash and white oak floors — are naturally light.

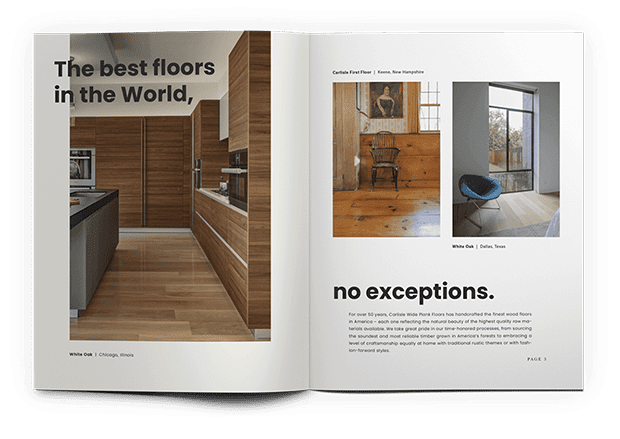

If you are considering having your floor stained, one of the best decisions you can make — depending on the quality of the stain and finish of course — is to have it prefinished. This can save time-on-site, make your installation go much quicker, and help you complete your project much sooner as well since there is no waiting for stain and finish to dry on-site – most builders love this option! Scott Bromley, Bromley Caldari Architects in NYC, chose a prefinished white oak floor stained Dark Chocolate for this Central Park South apartment renovation. As you can see, it’s absolutely stunning!

But you must be mindful of the process and the finish that is used on your floor. For example, most prefinished hardwood flooring today is mass-produced with a stain that looks painted on and a thick layer of finish that hides the grain and beauty of the wood — this is often done to hide the difference in quality and aesthetic of an inferior floor. It is also so hard, you need to hire someone if you ever want to touch up your floor — if it can even be touched up — in which case you need to replace the entire board or floor as wear and damage occurs.

The ideal process is to use an approved control sample with the color you have selected, on the wood you have selected, and making the floor to order. This is ideal for creating a consistent and cohesive look. The finish is also user-friendly and can be touched up with our dustless recoat system — no sanding, and a fresh finish in a matter of hours. You also want to think of the stain as an accent to the wood, the wood underneath still needs to be beautiful, durable, and stable. Don’t cover up a lower quality wood with a dark stain and expect the same results.

In Conclusion

Wide plank floors are more versatile than ever before, and if you work with the right flooring partner you can find a wood floor, and a finish to create just the right look. When it comes to selecting the right floor don’t just compare prices and samples, as they can be misleading. If the wood floor you order is the right color but only 4″ wide and 2′ long pieces, it will dramatically alter the overall look of your floor — wider planks make a dark wood floor look even more beautiful.

Be prepared to check your “specs” when ordering, whether you are looking at domestic or exotic flooring. Things to compare include the overall and average length and widths of the boards, — if you are using random widths. For example flooring, most manufacturers are only 2-4’ useable lengths. Unless the manufacturer has grading standards specific to creating an average length for the floor, this is not guaranteed. You need to make sure your floor does not arrive in all shortboards or it will seriously compromise the look of your floor.

Also inquire about how the wood is procured, cut, milled, and graded — this will determine not only the natural color of the floor but also how well it will accept a stain. Variations in procurement, drying and manufacturing processes will impact cost, but in the end, it will impact a lot more than that. Lower quality wood will be more difficult to stain, finish, and maintain, and they run a higher risk of negative performance and stability.

– – – – – –