Download our wood flooring buyer’s guide for helpful advice on how to choose and shop for wood flooring. Learn why wood is the superior flooring choice while exploring wood species, style, colors and textures. Understand durability, performance, installation options and more.

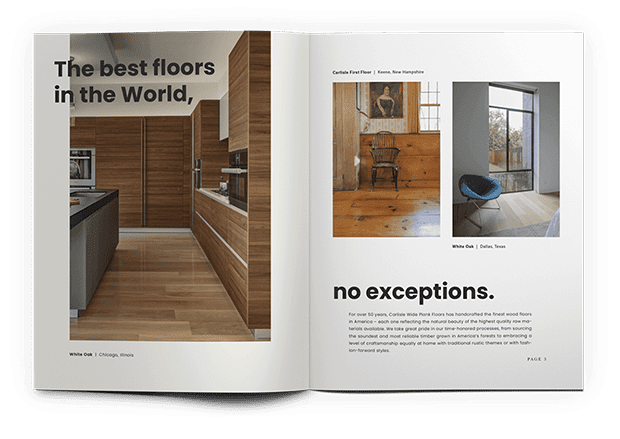

4 Benefits of Wood Floors Made in the USA

When you’re shopping for new hardwood floors, one of your first choices is between flooring products that are imported from abroad or flooring made here in the USA.

At Carlisle Wide Plank Floors, we’re big fans of domestic flooring products, because we hand make every one of our floors here in the USA specifically for each individual client. Why does it matter where your floor is made? Here are a few critical reasons:

Economic benefits of American Made Flooring: 100%

When you buy floors that are made in the USA with products sourced locally, you’re supporting local, regional and national businesses throughout the supply chain. Whether it’s the growers and sawyers who harvest the raw materials, the craftsmen who create the floors or the sales and service people who are your point of contact, your investment in domestic products helps provide jobs for American workers. Think of it this way: an imported floor purchased at $6 per square foot contributes about $2 per square foot or less to the American economy – about 33%. When you buy domestic, 100% of that $6 goes to American businesses.

Endless Inspiration for the Floor of Your Dreams

GET DESIGN BOOKReduced greenhouse gases

A lot of flooring products made overseas use timber shipped from the US. The finished floor is then shipped back to the US and delivered by truck to warehouse locations across the country, waiting for “final mile” delivery. That’s a long journey, which takes a lot of fuel. At Carlisle, most of our materials come from within 500 miles of our mill, consuming a lot less fuel and producing reduced greenhouse gases. Additionally, we recycle nearly 100% of our waste into bio pellets. Our finishes and adhesives are 100% CARB2 compliant, ensuring you’re protected against airborne toxic contaminants. That all adds up to the assurance that when you buy a Carlisle floor, you’re supporting sustainable and environmentally friendly production.

Reliable quality

When you buy floors from overseas, the wood used in your product may have traveled nearly 20,000 miles before it reaches your home. Monitoring and maintaining the quality of raw materials over that long journey becomes quite difficult, and there’s a greater chance the final product may not be as reliable as you want it to be. At Carlisle, the farthest that wood travels in our supply chain is 4,000 miles – when we ship a floor to California – which makes it much easier for us to monitor quality on a regular basis to ensure your floor is made from the highest quality materials.

On-time delivery

When you have selected the hardwood flooring you want for your home, the installation date can’t come soon enough. Yet the delivery of floors made abroad is often subject to lengthy delays. Production may be halted for weeks or months when materials and supplies are unavailable. And when the floors are shipped, there are so many more links in the supply chain where things can get held up. Even simple things like backlogs on container ships at the port can delay arrival for several weeks. At Carlisle, our domestic production process and supply chain have far fewer touch points, lowering the risk of delays and helping us provide on-time delivery.

Of course, there’s one more benefit of sourcing your wood floors from our facilities in New Hampshire: you can stop by and see your floor as it’s being made and meet the craftsmen responsible for handcrafting each and every plank!